Specifically, Fallbrook Technologies — NuVinci’s parent company — has integrated a NuVinci continuously variable planetary with an unnamed tier one supplier’s supercharger After extensive testing, the two companies concluded that a NuVinci-aided supercharger offers enough drivability and efficiency advantages to be worthy of OEM consideration. Said supplier is engaging with possible OEM customers, leading us to think a mainstream application of this technology might not be that far off.

To realize why Fallbrook sees appeal in this solution, it’s helpful to have a working understanding of superchargers, continuously variable transmissions, and the NuVinci.

Supercharging

Positive-displacement superchargers, the more popular supercharger style in the OEM segment, shovels a fixed air mass per compressor revolution into an engine’s intake manifold, courtesy of tightly meshed rotary pistons (lobes) that feed air in Roots-type blowers or the screws found in Lysholm types. From a power standpoint, this is useful because air induction is almost always the limiting factor for any engine type. But unlike the other major kind of forced induction, superchargers are an inherently parasitic ancillary since it gets driven from the crankshaft, which has always been a mark against superchargers in the long-lived supercharging vs. turbocharging debate.

Fallbrook’s supercharger prototype was developed with a centrifugal ProCharger supercharger on a 2008 Ford Mustang. Unlike its positive-displacement counterparts, a centrifugal supercharger is from the dynamic-compressor camp. Still driven off the crank, dynamic superchargers can change boost (and hence airflow rate) as engine speed rises and drops.

CVTs

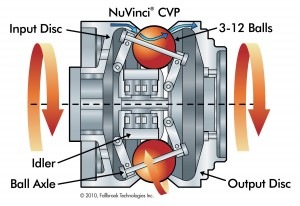

The basic principle of continuously variable transmissions is that since they aren’t constrained to a finite number of gears with strict ratios, they can keep a power source (i.e., an engine) at its peak output range. The NuVinci CVP is such a device, consisting of two ring gears (one for input and one for output), an inner ring of balls (the planets) immersed in a specially formulated lubricant and mounted between the two ring gears, and a central cylinder that helps hold everything together (the sun). If the NuVinci were used as an actual car transmission, engine torque would flow from the input ring through the balls (all spinning, by the way) to the output ring, and then on to driveshafts and the wheels – voila, propulsion. In the interest of providing mechanical advantage, the balls can be tilted toward the input ring, changing the rotational distance in favor of the input ring for underdrive (the input gear is spinning faster than the output over a given amount of time). Conversely, overdrive is achieved by tilting the balls toward the output.

Why do it?

Now that you know how superchargers and NuVincis work, here’s the skinny on why Fallbrook wants to combine the two products. If you’ve ever looked at flow maps that plot a supercharger’s efficiency – intake air flow on the x-axis vs. pressure ratio on the y-axis with supercharger revolutions included as slopes – you’ll know they’re most efficient within a predetermined range. Typically, the greatest efficiency is found in a relatively narrow area near or around the middle of the supercharger’s operating range. Say a Roots-type supercharger has 76-percent peak efficiency, which is pretty good for a Roots-type. At lower and higher rotational speeds, the supercharger can be anywhere from 60-75-percent efficient, despite pushing the same amount of air per revolution from lobes to manifold. Pumping leakage around the lobes sap efficiency at low and high speeds; at higher speeds, the air can get heated to the point that it’s detrimental to engine health and robs power. Let’s not forget the supercharger’s speed is essentially at the mercy of the crank and the associated auxiliary gearing too.

A NuVinci sitting on the supercharger’s input shaft would allow for more precise speed control by way of the planetary’s tilting balls. At low crank speeds, NuVinci could give the supercharger an efficiency advantage by spinning it more quickly, preserving throttle response while moving into the optimal efficiency range sooner. Slowing the supercharger to keep it in the optimum efficiency window at higher engine speeds would be golden too. Tailoring supercharger speed against the crank speed for maximum efficiency would be the control software’s job. In essence, NuVinci would permit smaller-displacement engines and superchargers since engine builders could size for peak power instead of torque. An engine making the most of the air available to it at all times would be a very efficient solution. Challenges in this project include getting the control software right and properly packaging the NuVinci, not to mention the typical supercharger demands.

Maximum output with minimum input. The guiding directive for all engineering efforts.